|

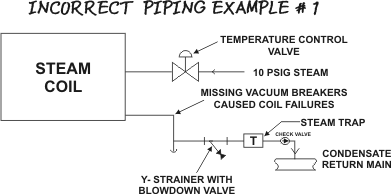

Failure Example # 1 |

|

Here is an example of both faulty design and installation. Back in the 1960's when I was a young sales engineer working for TRANE, I kept receiving numerous unsolicited orders for large replacement steam coils from a huge DuPont synthetic fibers manufacturing plant in Waynesboro, Virginia. It was good business and I wasn't asking any questions. I was even thinking that perhaps Trane steam coils were not on a par with other better known Trane products such as CENTRAVACS (centrifugal water chillers). |

|

| Finally, my day of reckoning came when I received a heated phone call from the DuPont pipe shop foreman who had been requisitioning these many dozens of replacement steam coils. He was not a happy camper and he demanded to know why his Trane steam coils kept failing. He was particularly concerned because he was about to replace six 33” high x 120” long coils in a roof-mounted make-up air system at a budgeted cost of $25,000. Remember, these were 1960 dollars! They would probably cost $75,000 to replace in today’s dollars! |

||||

|

The piping installation of these failed coils was almost perfect except for one minor but critically important omission. Vacuum breakers which are an absolute must had never been installed by DuPont. A phenomenon known as pinholing had resulted causing numerous leaks in the outer condensing tubes of these steam distributing coils. Since such steam coils cannot be repaired, replacement was, and still is, the only alternative. |

|||

This is one of the most obvious (but still frequently violated) of my 16 fundamental rules of good piping practice. I can easily teach them to your maintenance personnel as part of my on-site customized steam training. Visit Failure Example #2 for another example of why incorrect steam piping is always extremely costly to you! |

||||

© 2008 Steamtraining.com. All rights reserved. Terms of Use and Disclaimer |

||||||